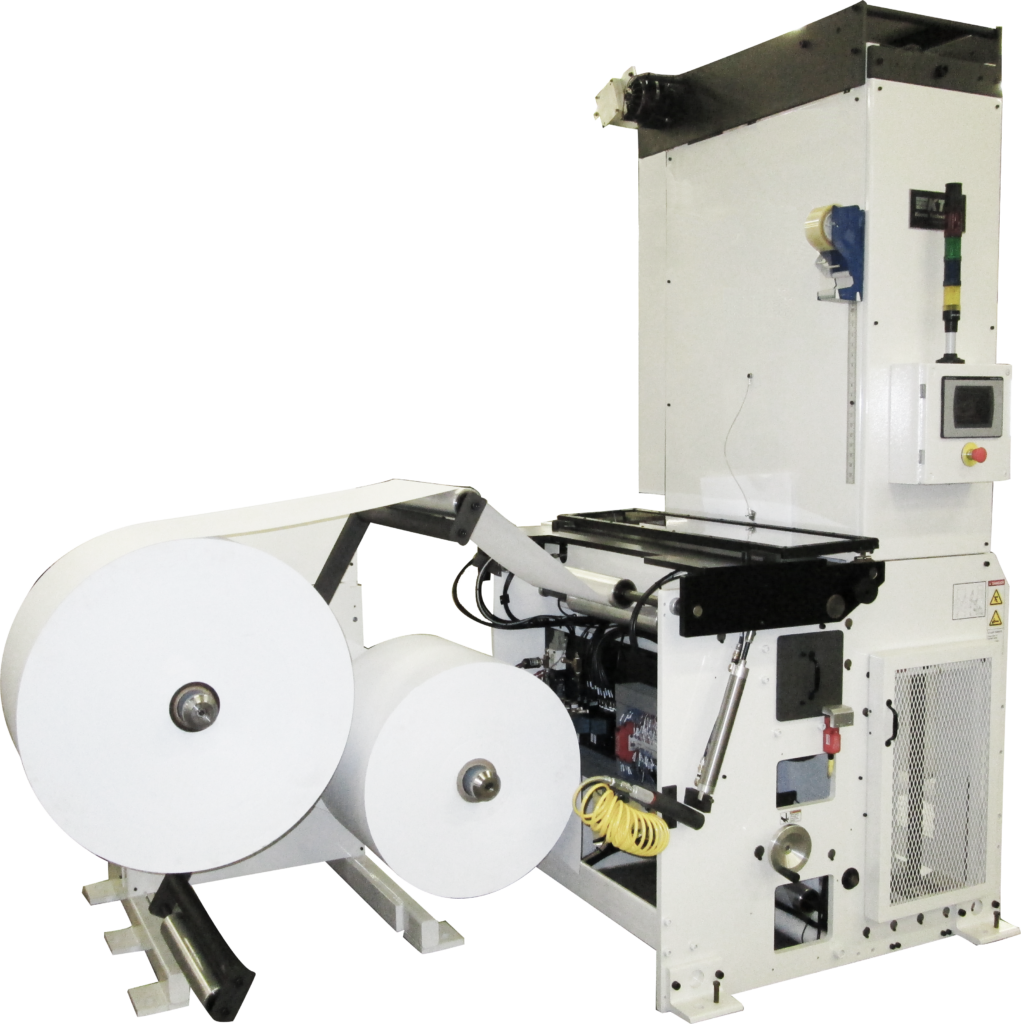

Caledonia, IL, February 2021 – KTI, a world-class manufacturer of automatic splicers, turret rewinders, and other web converting equipment, has recently completed installation of their ZC Series Cantilever Butt Splicer for McCracken Bag and Label Co.

McCracken Bag and Label Co. has been providing labels, tags, and paper bag solutions to a variety of industries for over 100 years. They know the KTI product line to be reliable through their years of experience working together. McCracken currently has almost a dozen KTI machines running in their distribution center including an older model of the ZC Series Automatic Splicer that has been very reliable for them, making the latest model an easy choice.

McCracken Bag and Label Co. plans to run mostly pressure-sensitive labels and some unsupported papers and films. They specifically chose the ZC Automatic Butt Splicer to reduce waste and increase productivity. The Butt Splicer’s two cantilevered roll positions feed a continuous supply of material into the press, and the integrated storage festoon eliminates the need to stop for changing rolls saving time and material waste.

The ZC is the perfect fit for McCracken Bag and Label Co., as it is a high-performance, cost-effective splicer adaptable for many different applications. Machine customization allows for running a variety of materials including paper, label stock, film, tag and other specialty materials. Increased profits and productivity with reduced waste are just a few of the reasons customers, including McCracken, choose the ZC Series Automatic Butt Splicer.

Chris Buday, Vice President of Business Development, at McCracken Bag and Label Co. says “My relationship with Steve Reynolds (Regional Account Manager) and the support he & KTI have provided over the years, as well as the reliability of the equipment, is the driving force behind continuing to purchase from KTI. I look forward to continuing the relationship for many years to come.”

“We take pride in our after-market support and continuing relationships after the sale. Steve Reynolds has extensive experience with this due to his previous role as Service Manager for KTI”, says Derek Wheeler, VP of Sales for Quantum Design. He goes on to say “we strive to build long-lasting relationships with customers and our ongoing business with McCracken is a testament to our goals of offering cost-effective solutions with the ongoing support needed to create the highest level of customer satisfaction.”

The ZC Series Cantilever Butt Splicer is available in web widths up to 22 inches (558mm), roll diameter up to 60 inches (1524mm), splice speed up to 1000FPM (304MPM) and runs 3 inch (76mm) cores. Standard features include PLC touch screen controls, automatic zero speed butt splice at process line speed, diagonal butt splice with no overlap, two-sided tape, automatic roll side lay and bi-directional unwind capability.

Optional features available for the ZC Series Cantilever Butt Splicer include in-register splice system for pre-printed webs, spiral grooved rollers, automatic de-curler, integrated roll loading dolly, roll loading cart, and core adaptors for alternate core sizes.

For more information on the ZC Series Cantilever Butt Splicer CLICK HERE.